|

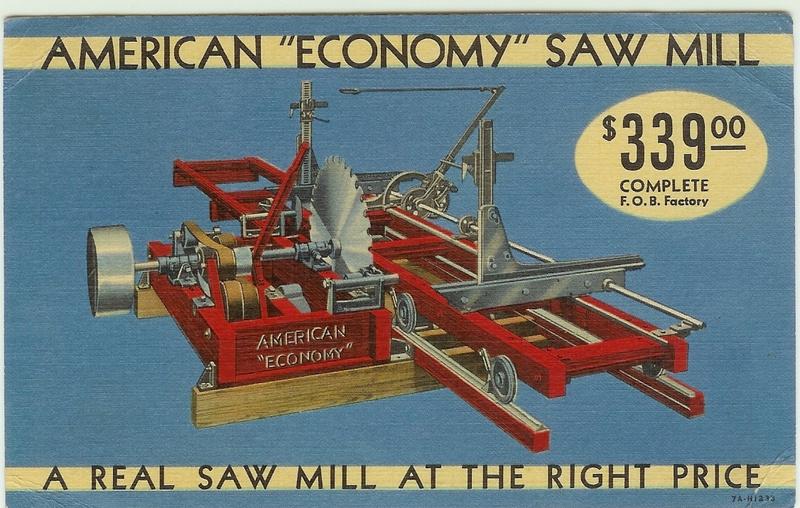

| While not our Sawmill, it's an ad copy of the economy size |

Anyways, I ran the engine, a Caterpillar diesel from the 1950s. I would engage the clutch to get the mill running and disengage the clutch to kill it. To engage, you have to push a large black rod into an upright position without going too fast. Going too slow isn't an option either as it takes muscle to engage, just not too much muscle. It seemed as soon as I engaged it the head sawyer told me to disengage it. That or it would just run and run, and I would feel like I need to shut this down.

|

| The clutch disengaged |

Second, the raw power of that blade. It really strikes fear into you when you see it just disintegrate the wood. It's amazing to see the sawyers struggle rotating a log on the cage, the carriage that carries the log into the blade, and then watch the blade treat the log like it was pudding.

|

| Rolling the log |

Third, it took me a long time to be comfortable with the placement of the other sawyers. It shows you the training involved with the sawyers and the personal awareness needed by a sawyer. One needs to know his or her surroundings at all times and still be confident enough to employ tunnel vision to finish an aspect of the job. What I'm getting at is the blade needs to be feared enough but yet defeated enough that you can keep the blade clear so no real injuries occur.

Fourth, back to waste, one can see why particle board and various other repackaging of wood occurred. One is left with many tiny pieces, crooked pieces, and more oddities to get perfect slabs. Instead of just wasting the lower quality wood, companies found a way to use it. One day sawing shows you this need. I will never curse particle board again.

|

| All the dust from Sunday produced by a small log |

All in all, the experience was dusty, loud, and fruitful. Thank you gentlemen for letting me be a part of the sawing. Some new research items though for me: the deafness of sawyers, "sawdust" lungs, and the history of particle board and other repurposing of the unfit slabs.

Image:

http://www.hackettstownlife.com/forum/382532

No comments:

Post a Comment